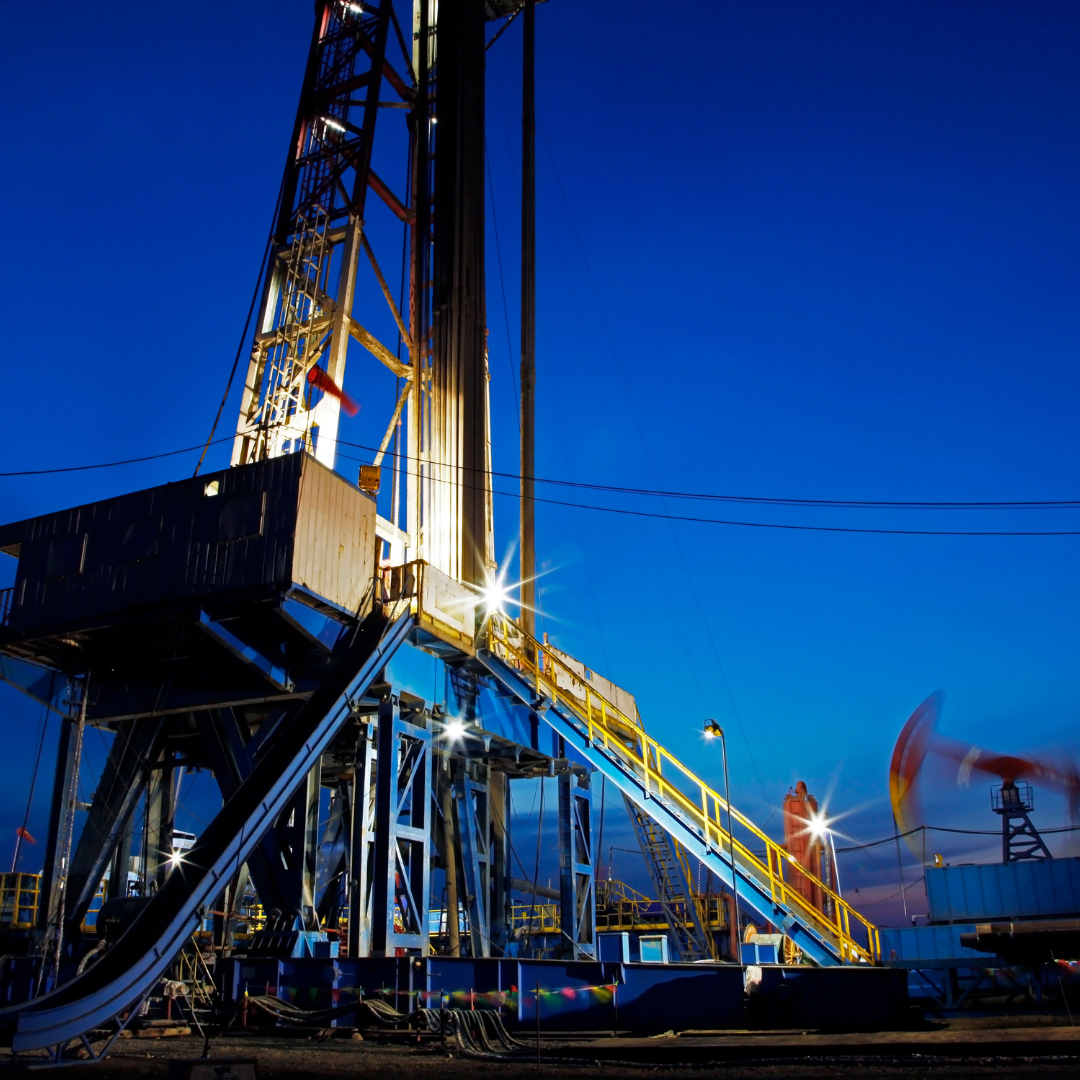

STEEL INDUSTRIES

Forged for Extremes. Engineered for Precision

Engineered for the Extremes.

Designed for Every Stage.

Steel Industries delivers advanced downhole completion systems: from thermal SAGD to flow control and water mitigation.

Engineered in the UAE, deployed across the globe.

Precision tools. In-house innovation. Unmatched performance under pressure.

Engineered Locally, Diversified Globally

Engineered and assembled in-house, with full control over design, testing, and manufacturing, ensuring every tool meets our exact performance standards before it reaches the field.

Optimizing completions through isolation, control, thermal performance, and water management.

Engineered for every phase. Steel Industries tools power plug-and-perf, multi-stage stim, SAGD, and steam flood completions.

Global reach with regional inventory and deployment support, ensuring fast tool availability, local responsiveness, and efficient mobilization wherever your operations are

Comprehensive Tool Suite

Liner Hangers & Cement Retainers — Reliable suspension systems and zonal cementing integrity for vertical, deviated, and thermal wells.

Bridge & Frac Plugs — High-differential pressure isolation for plug-and-perf and multi-stage stimulation programs.

Inflatable & Production Packers — Secure annular sealing in challenging wellbore geometries and high-temperature cycles.

Flow Control Systems — Multi-zone inflow management using sliding sleeves, ICDs, and isolation valves, optimized for production balance and water control.

Water Shutoff & Coning Control Tools — Mechanical and swellable packers, selective sleeves, and zonal diverters designed to reduce unwanted water production and improve drawdown efficiency.

Service & Setting Tools – Precise deployment systems for plug setting, liner placement, and completion tool activation, manual, hydraulic or electric.

Integrated Completion Strings – Seamless tool compatibility from heel to toe, reducing run complexity and improving downhole reliability.

From Alberta Canada & Latin America to the Middle East

Steel Industries specializes in completion systems for high-temperature and steam-injection environments, including tools designed for long-term heat exposure, thermal expansion, and fluctuating pressure cycles.

SAGD Deployments – Complete injector and producer strings with steam-rated packers, thermal liners, sand control, and embedded sensor arrays for real-time monitoring.

Cyclic Steam Stimulation (Huff & Puff) – Steam-compatible, retrievable packer systems and flow control tools that withstand repeated injection-soak-production cycles.

Steam Flood Optimization – Zonal injection valves, isolation packers, and diverters tailored for fine-grained steam distribution and sweep efficiency in heterogeneous formations.

High-Temp Water Shutoff – Thermal-grade water shutoff tools that target unwanted water production during or after steam operations, extending productivity in heavy oil reservoirs.

Thermal Coning Control – Smart sleeves and pressure-balancing tools that prevent steam or water breakthrough and preserve reservoir integrity under aggressive drawdown.